Durable Labels

There's a place for inexpensive paper labels with short-term adhesives, and it's not in heavy industry, outdoors, in laboratories, or in warehouses. There, durable labels rule, because our customers need to be able to identify and track their goods over the long term. Durable adhesive labels are meant to be applied to durable commodities, so they're designed to last 2-3 years or more – the exact opposite of packaging labels, which are discarded at point of use.

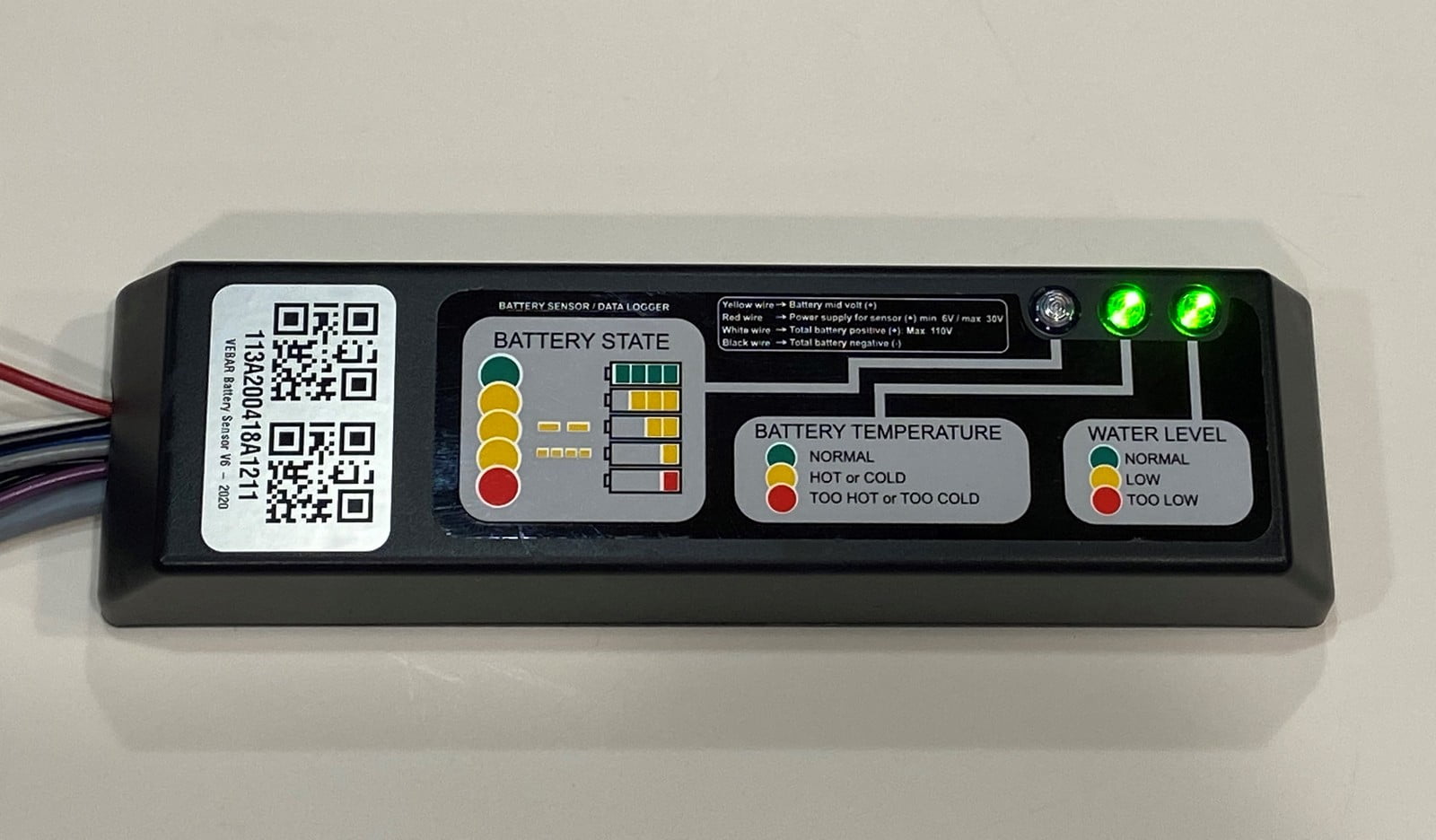

Custom printed durable labels have specific requirements most adhesive labels don't. It's no surprise that the substrate material for industrial labels and other durable labels has to be tough, so most are made of robust plastics like vinyl, polyethylene, polypropylene, and polyester. Vinyl labels are especially useful and versatile. But inks on self-adhesive durable labels also have to be able to withstand temperature extremes, abrasion, flaking, chemical and oil residues and spills, water contact and immersion, and weather, while retaining their legibility. Probably the most important element of any durable labels – especially durable industrial labels, and to a lesser extent durable custom decals – is the adhesive. It doesn't matter how tough your durable and industrial labels are if the adhesive releases and falls off, or can be peeled off by accident or by a bored kid or employee.

The ability to adhere under any circumstances is especially important for drum & barrel labels containing potentially toxic chemicals; chemical proof labels for reagent containers; or custom printed industrial labels meant for government-mandated warning purposes. And let's not forget custom printed durable decals and stickers meant for hard-to-label items like rubber tires, which are easy to mix up if they're not properly labeled.

Etiquette Systems is specially equipped and prepared to provide a wide variety of custom printed durable & industrial labels as well as durable custom decals, all with quick turnaround times. Our durable adhesive labels and decals, both custom and blank, are made using four different types of adhesives that we ALWAYS keep in stock. While we pride ourselves as a durable label printer specializing in custom printed durable labels, we're versatile enough to understand that some customers need to print their own labels onsite. While we use a press for our custom durable labels, we've made sure that the blank durable labels we supply can also accept thermal, laser, and inkjet printing, including color versions of the last two.

Our most economical durable label adhesive works very well with substrates of a variety of types, including all plastics and metalized materials. It's emulsion based, and remains effective under a wide range of environments and conditions – far more than most uses will ever require. You'll find that all our durable label materials exceed specifications. We snub any so-called durable adhesive label materials that barely scrape by regulatory requirements. There's too much at stake to take chances with subpar labels, especially those intended as durable industrial labels.

Some blank and custom durable labels, however, require even more stringent controls. This is where our two solvent-based adhesives come in. One is specially designed to stick to hard-to-label surfaces, including those that have been varnished, are slightly oily, or otherwise reject most adhesives. This material is ideal for chemical proof labels, chemical container labels, drum & barrel labels, and similar labels intended for surfaces that might otherwise prove impossible to label. The other solvent-based durable adhesive was designed for labeling rougher surfaces, from plastic to wood, as well as those durable labels meant for use outdoors - so it can be used for pallet labels, weatherproof labels, waterproof labels, and the like.

Other durable adhesive labels make use of a special rubber hybridized acrylic (RHA) adhesive, perfect for applying to surfaces both rough and oily, as well as powder-coated parts and drums. Even better, these durable labels are repositionable: depending on the substrate used, they can be taken off and reapplied without ruining the label (much less marking the product or container). It's perfect for use in tough environments and at high speed, resulting in some of the most some versatile self-adhesive durable labels available.